Dosing Pump

Injection Valves

Chemical Dosing Pump

Injection Valves

Dosing pump injection valve with non-return valve serves a number of critical functions

ensuring the metering line remains free of chemical air-locks by generating a defined back pressure between

the dosing pump and injection point eliminating backflow into the metering line, protection against excess chemical

discharge or syphoning occurring particularly when mounted in zero pressure environments such as tanks and

vessels and ensuring the chemical metering line remains primed and intact.

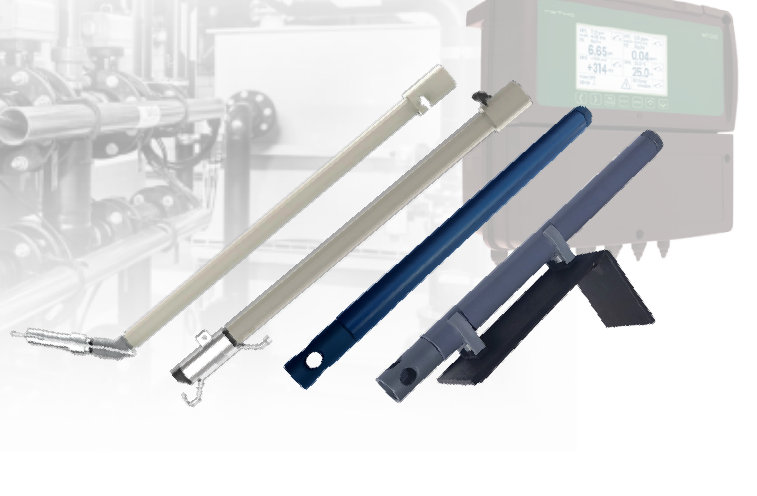

Injection Valves PVDF

Injection valve manufactured in PVDF characterised by exceptional resistance to most aggressive chemicals

agents with hastelloy spring ceramic ball non-return valve and chemical resistant seals, tubing is connected

via the specially designed compression system suitable for high pressure applications providing an impermeable

chemical seal connection.

Technical Details

• Standard Seals Viton or EPDM ( Special

seals available on request )

• Compatible Tubing Material :- PVC - Polyethylene - PTFE - PVDF

• Tubing Sizes :- 4x6mm ( 18 l/hr Max) 8x10mm (110 l/hr Max )

• Supplied with dual

purpose male BSP installation threads

N.B. Compatible with most chemical dosing pumps

Chemical Dosing Pump

Injection Fittings

Dosing pump injection fitting with non-return valve serves a number of

critical functions ensuring the metering line remains free of chemical air-locks by generating a defined

back pressure between the dosing pump and injection point eliminating backflow into the chemical metering

line, protection against excess chemical discharge or syphoning occurring particularly when mounted

in zero pressure environments such as tanks and vessels and ensuring the chemical metering line remains primed and

intact.

Injection Fittings PVDF

Injection fitting manufactured in PVDF characterised by exceptional resistance to most aggressive chemicals

agents with hastelloy spring ceramic ball non-return valve with chemical resistant seals, tubing is connected

via specially designed compression system suitable for high pressure applications providing an impermeable chemical seal

connection

Technical Details

• Standard Seals Viton or EPDM ( Special seals available on

request )

• Compatible Tubing Material :- PVC - Polyethylene - PTFE - PVDF

• Tubing Sizes :- 4x6mm (18 l/hr Max) 8x10mm (110 l/hr Maz)

N.B. Compatible with most chemical dosing pumps

Chemical Metering Pump

Injection Valves

Metering pump injection valve with non-return valve serves a number

of critical functions ensuring the metering line remains free of chemical air-locks by generating a

defined back pressure between the dosing pump and injection point eliminating backflow into the chemical metering

line, protection against excess chemical discharge or syphoning occurring particularly when mounted

in zero pressure environments such as tanks and vessels and ensuring the chemical metering line remains primed and

intact.

Injection Valve PVC

PVC injection valve with male BSP thread excellent chemical resistance with lip non-return valve

mechanism that eliminates any potential chemical air-locks and highly reliable in maintaining a primed metering line,

benefits from an impermeable chemical seal connection between the tubing and fitting is maintained through the

hose compression system.

Technical Details

• Standard non-return material seal Viton - EPDM

(available on request)

• Compatible Tubing Material :- PVC - Polyethylene - PTFE - PVDF

• Tubing Size Connections :- 4x6mm - 8x10mm - 10x14mm

N.B. Compatible with most chemical dosing pumps

Chemical Metering Pump

Injection Fittings

Metering pump injection fitting with non-return valve serves a number

of critical functions ensuring the metering line remains free of chemical air-locks by generating a

defined back pressure between the dosing pump and injection point eliminating backflow into the chemical metering

line, protection against excess chemical discharge or syphoning occurring particularly when mounted

in zero pressure environments such as tanks and vessels and ensuring the chemical metering line remains primed and

intact.

Injection Valve PVC

Injection fitting manufactured in robust PVC with male BSP thread excellent chemical resistance with

highly efficient non-return valve mechanism that eliminates chemical air-locks and ensures metering discharge

line remains primed, the impermeable chemical seal connection between tubing and fitting is maintained through the

simple hose compression system.

Technical Details

• Standard non-return material seal

Viton - EPDM (available on request)

• Compatible Tubing Material :- PVC - Polyethylene

- PTFE - PVDF

• Tubing Size Connections :- 4mm x 6mm - 8mm x 10mm

N.B. Compatible with most chemical dosing pumps

Electronic Dosing Systems

Tel 01299 825 656 Email info@electronicdosingsystems.co.uk

Solutions For All Metering & Measurement Processes

What is a Dosing Pump Injection Valve

An injection valve is the final "point of entry" in a chemical dosing loop it's primary function

is to generate a specific amount of backpressure to the dosing pump and to ensure chemicals are dispersed evenly into the flow

stream while preventing the process liquid from backing up into the dosing pump discharge line, integrating a high-quality injection

valve offers several technical and operational benefits often incorporating a spring loaded non-return valve that act as a specialized

check valve providing an artificial head pressure ensuring each stroke of the pump delivers a precise repeatable volume of chemical.

Elimination

of Siphoning

Processes that have the point of injection lower than the chemical storage tank gravity can cause chemicals to effectively "free-flow"

into the system even when the dosing pump is off to guard against this happening the injection valve

non-return mechanism plays a critical role by requiring a specific pressure to open effectively "locking" the line

against accidental siphoning.

Maintenance Simplicity

Most modern injection valves are designed for tool-free servicing requiring periodic cleaning

often being the most likely component to fail mainly due to chemical crystallization at the injection point into the

pipework they are designed to be easily removed and serviced without dismantling the entire discharge line.

Copyright: - Electronic Dosing Systems 2026

| Water Treatment | Electroplating | Cooling Towers | Industrial Boilers | Paper Industry | Vehicle Washing |

Wastewater | Swimming Pools & Spas |

| Beverage & Brewery | Petroleum | Bottle Washing | Hygiene &

Cleaning | Biotechnology | Food Industry | Pharmaceutical Industry |

Pumps & Accessories

pH & Redox Instrument

Dosing Pumps

Dosing Pumps

Hazardous Areas Zone 2

Dosing Pumps

Dosing Pumps